- Email: vicky@hbruixin.net

- WhatsApp: 18622802373

News

-

Learn More About Rotary File Types

Rotary files include tungsten carbide rotary files, which are made of high-quality tungsten carbide materials, also known as tungsten steel rotary files; high-speed alloy steel rotary files, which are made of high-quality high-speed alloy steel materials. They are usually used in conjunction with...Read more -

Important Guidelines for Safe and Effective Use of Rotary Files

To ensure your safety and maximize the performance of our tool, we would like to provide you with the following important usage guidelines. Kindly read them carefully and adhere to them. I. Safety Precautions 1-B...Read more -

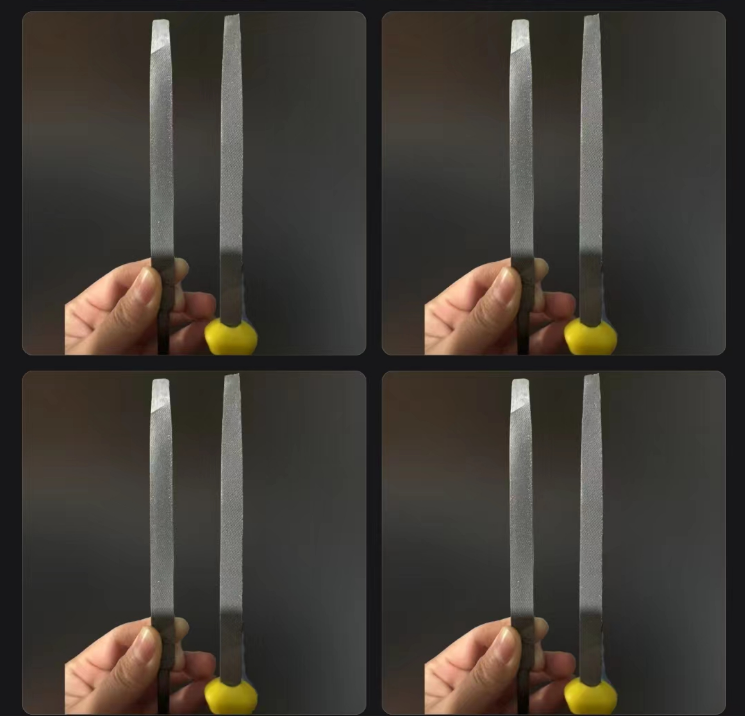

Differences between heavy-duty triangular files and regular triangular files

If there are two triangular files placed in front of you, do you know which one is most suitable for you? heavy-duty triangular files and regular triangular files Certainly! Here’s a summary of the differences between heavy-duty triangular files and regular triangular files: 1. Width of Cut...Read more -

The choice of precision craftsmanship, rotary files help you carve perfect craftsmanship

At the intersection of manufacturing and craftsmanship, every detail determines quality. As a treasure among precision tools, rotary files are an outstanding choice that combine fine craftsmanship with high efficiency. First of all, the rotary file is intelligently designed. Its fine filing surfa...Read more -

“The Unsung Hero: A Ode to the Humble Screwdriver”

In the vast toolbox of life, where power tools scream for attention and flashy gadgets glitter with promises of modernity, there exists a quiet hero, often overlooked yet indispensable—the screwdriver. This unassuming tool is more than just a metallic shaft with a twist; it’s a symbol of si...Read more -

Annular cutter: Exploring the Excellence of Annular Cutter

In the realm of metalworking and fabrication, the quest for precision and efficiency has led to the development of innovative tools, and at the forefront of this evolution are annular cutters. These specialized cutting tools have revolutionized the way industries approach hole-making processes, o...Read more -

Craft Your Own Kit: Unleash Your Creativity with the 5PCS Carbide Burr Set!

Hey, creators and innovators! Ever feel like your projects demand a bit more pizzazz, a touch more precision? Well, buckle up because we’ve got the perfect solution for you – our “5PCS Carbide Burr Set.” In this blog, we’re not just talking about a tool; we’re talki...Read more -

Twists drill bit:A leader in the hardware tool industry.

Twists drill bit:A leader in the hardware tool industry. Fried Dough Twists drill bit is a common type of drill bit. Its shape is like Fried Dough Twists, so it is named. Fried Dough Twists bits are widely used in drilling, drilling, reaming and other work situations. Fried Dough Twists drills c...Read more -

Hollow drill shank classification and usage instructions

The main handle types on the market are divided into universal handles, right-angle handles, overtone handles, and threaded handles. Universal handle Those with three holes in a plane, or only three holes, are universal handles, also known as Nitto handles. They are special handles for Japanese N...Read more -

Shine Bright with the Perfect Pick: Choosing Diamond Steel Files!

Greetings, fellow seekers of precision and sparkle! Whether you’re a DIY diva, a savvy retailer, or a wholesale wizard, your journey to select the right tools begins here. Welcome to the dazzling world of “Diamond Files Set.” In this blog, we’ll explore these shining stars...Read more -

Carbide Burrs: The Tiny Tools with Big Impact

In the world of machining and metalworking, there are numerous tools and accessories that play vital roles in creating precision parts and adding intricate details to various projects. One such unassuming yet indispensable tool is the carbide burr. These small, versatile cutting tools have a surp...Read more -

The Importance of Innovation in Modern Business:

Innovation has become the lifeblood of modern business, driving growth, fostering competitiveness, and propelling industries forward. In an era defined by rapid technological advancements and ever-evolving consumer expectations, businesses must prioritize innovation to stay relevant and sustainab...Read more