Diamond Grinding Needle-Abrasive Tool

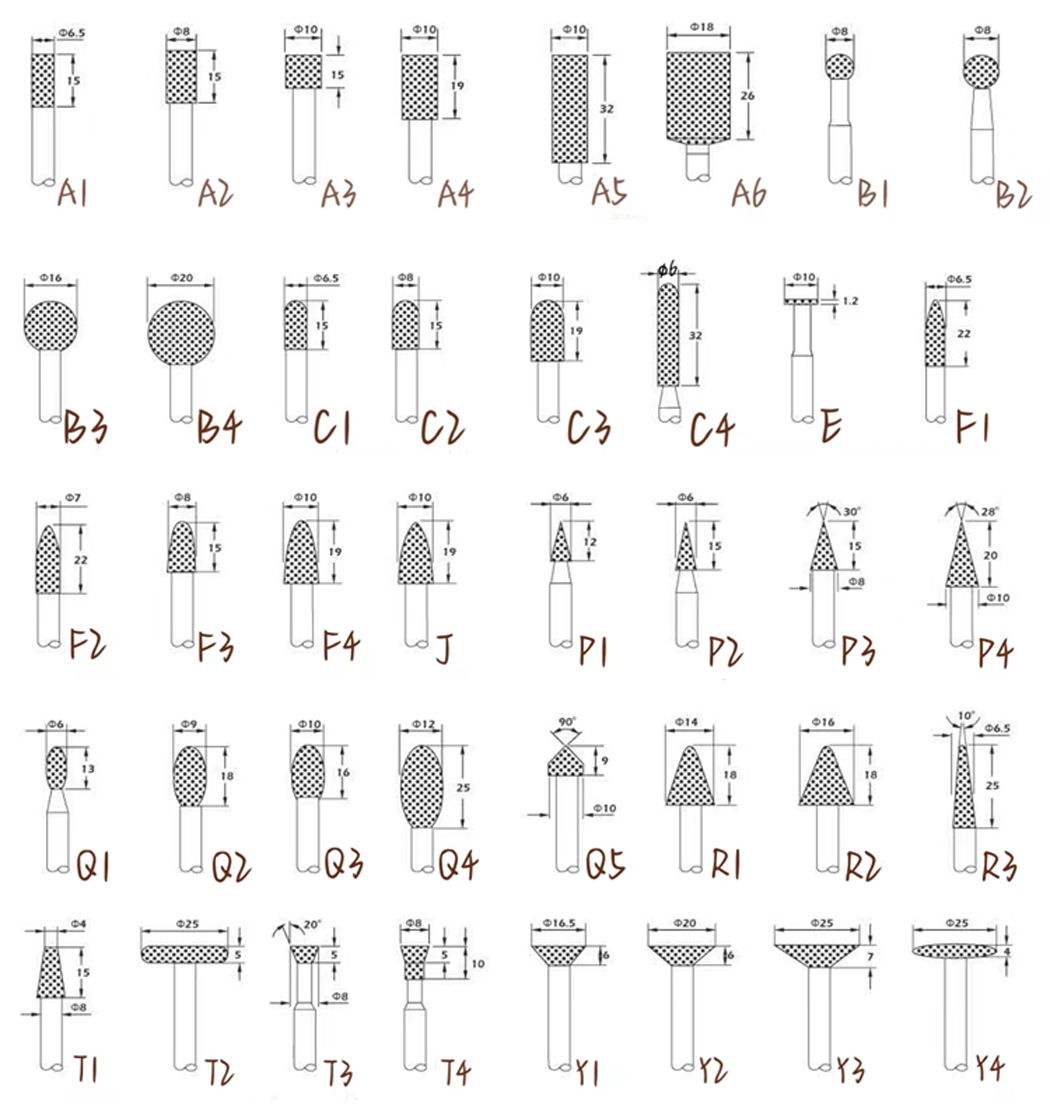

Modle Profile

Product Basic Information

Product Name: Diamond Grinding Needle

Product Model: A/B/C/E/F/J/P/Q/R/T/Y

Head Material: Diamond

Quantity: 30 pcs/set, 20pcs/set

Total Length: 45mm-60mm

Shank Diameter: 2.35mm/3.0mm

Usage: Mold processing and repair, jade and glass grinding, cleaning flash, burr and weld of casting and forging, inner hole surface of various mechanical parts, etc

Advantages: High quality emery is durable, sharp and wear-resistant, and has a wide range of applications.

Product Introduce: This product adopts diamond coating, mainly used for fine carving wood, metal and other products.

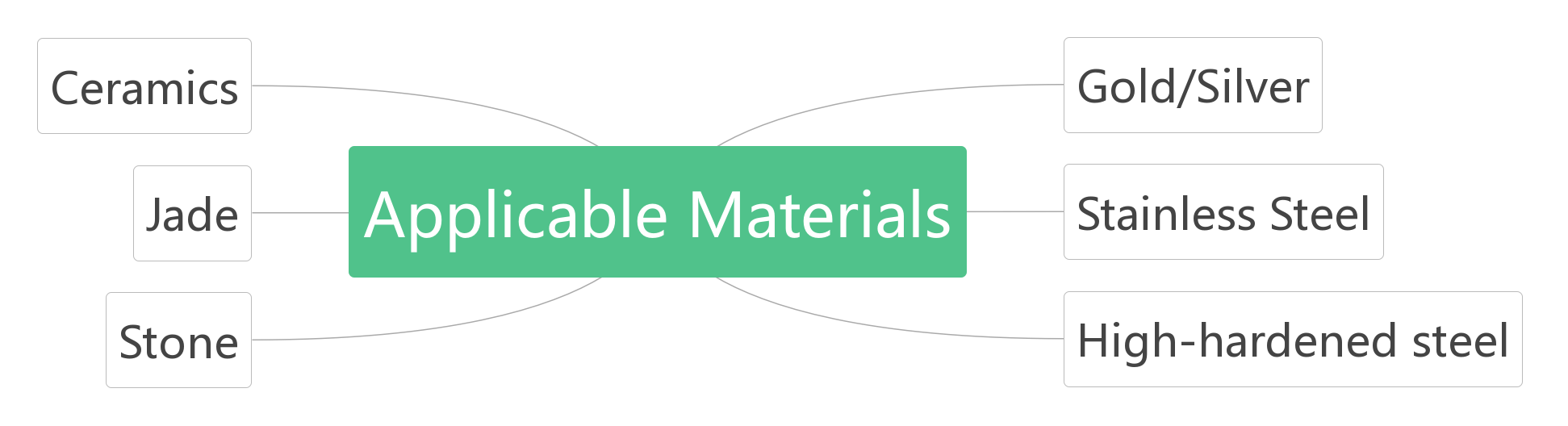

Applicable Materials

Jade

Ceramics

Stone

Steel

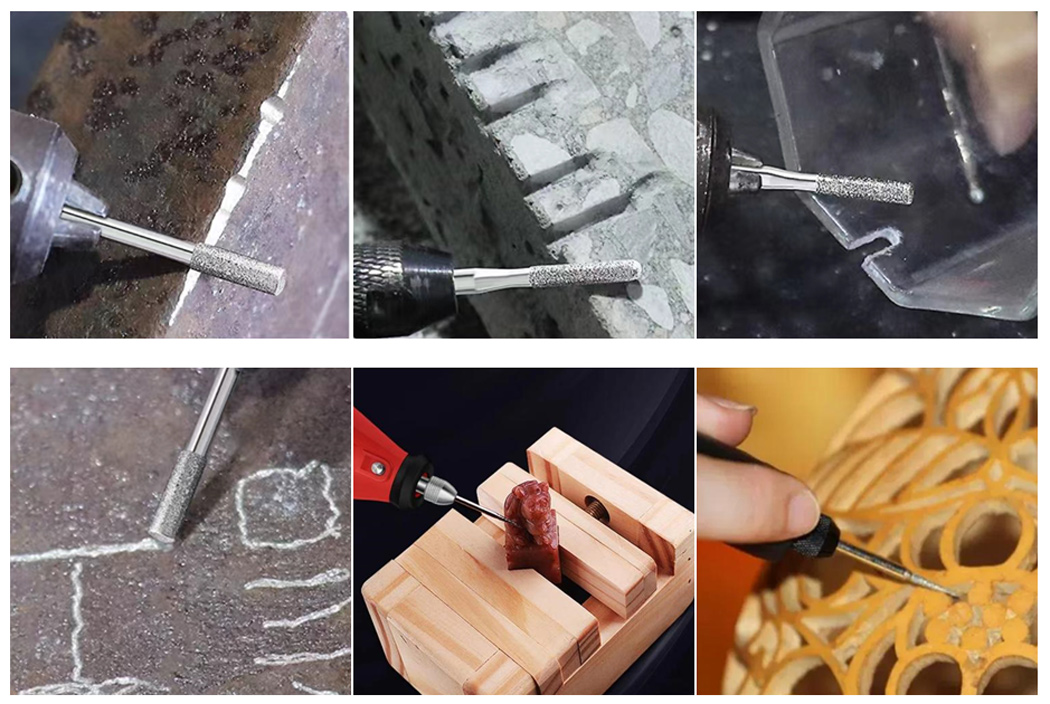

Application

1. Mainly used for grinding and carving of jade, glass, ceramics, stone, hard alloy, crystal and other hard materials; Add water for cooling when using.

2. Mold processing and repair; Stone carving carving, cutting line, polishing hollow cleaning burr weld, tooth grinding processing; Chamfering and grooving of all kinds of mechanical parts, cleaning pipes, inner holes and surfaces of finishing parts.

Package

Applicable Scenario

Advantage

1. High quality material, wear-resistant and durable, long service life.

2. Provide a variety of specifications, widely used.

3. Sharp products, high grinding efficiency.

4. No dust pollution.

5. Alloy forged handle, hard and durable.

RuiXin Advantages

1. We are professional carbide burr manufacturer since 1992. With 30 years of abrasive tools, and the grinding time of workpieces is definitely longer than that of others.

2. Our material is 100% Premium diamond. Some factory used cheapest material to make worse quality by cheaper price.

3. Some regular code have stock and can be shipped out within 7 days!

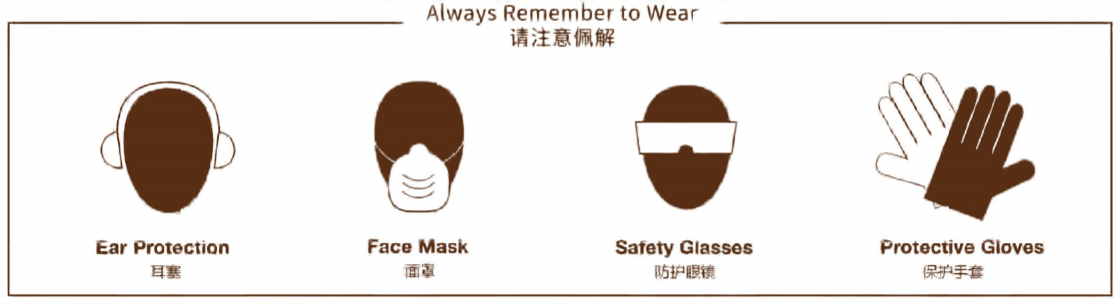

Attention

Precautions:

First idle for 1 minute, and make sure that the grinding rod is firmly installed without jumping. Otherwise, the grinding operation cannot be carried out directly, which may cause damage to the grinding head and the polished things are not smooth.

Adjustment method:

1. Gently tap the high-speed grinding rod handle with a small wrench for changing the collect until the grinding head. Until the stable position; It is forbidden to knock the electronic machine. The adjustment method is to loosen the collet, turn the grinding head to an angle or extend and lock it a little, and then tighten it again.

2. Add water for cooling (similar to the dripping device in the hospital), because dry use will graphitize the diamond on the grinding head due to overheating, thus accelerating wear and scrapping.

3. Try to avoid shaking during drilling. Shaking will cause local damage to the grinding head and accelerate the damage of the whole grinding head.

4. The speed shall be as high as possible, and the speed is generally required to be no less than 10-20 M / s.

5. Press gently. The diamond grinding rod processes the workpiece by grinding. If you use too much force, the grinding powder is not easy to discharge, and the grinding head (especially the small-diameter grinding head) is also easy to be damaged.

6. Adding water to the diamond grinding rod can improve the wear resistance and sharpness of the grinding head, and then improve the service life.