The selection and use of the material and model of the milling cutter depends on the processing material and processing purpose.

Below are some common milling cutter grades and selection suggestions:

1.High-speed steel (HSS) milling cutter: suitable for processing some hard materials, such as steel, cast iron, stainless steel, etc. Machining can be done with dry (no lubrication) or wet cooling.

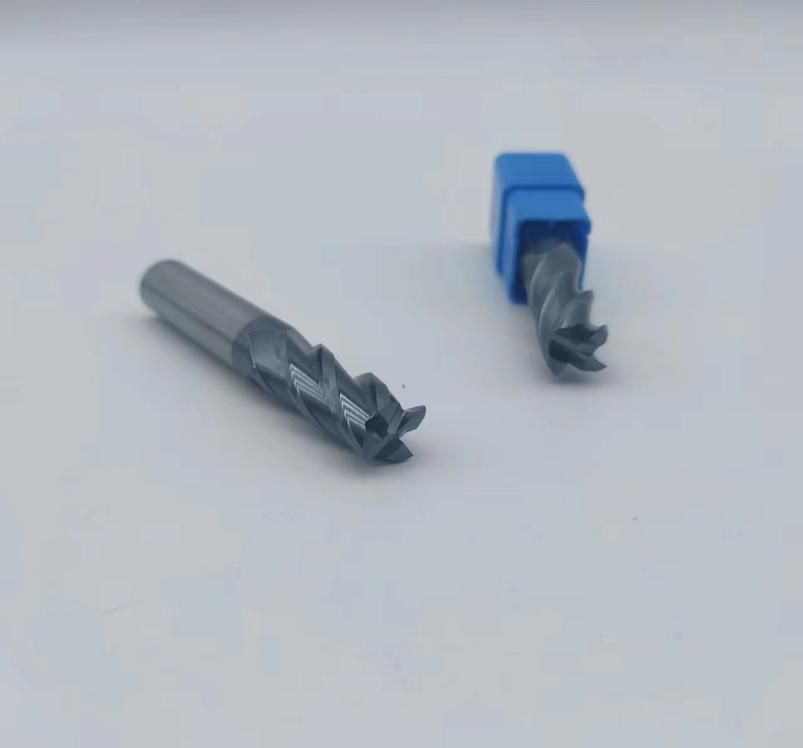

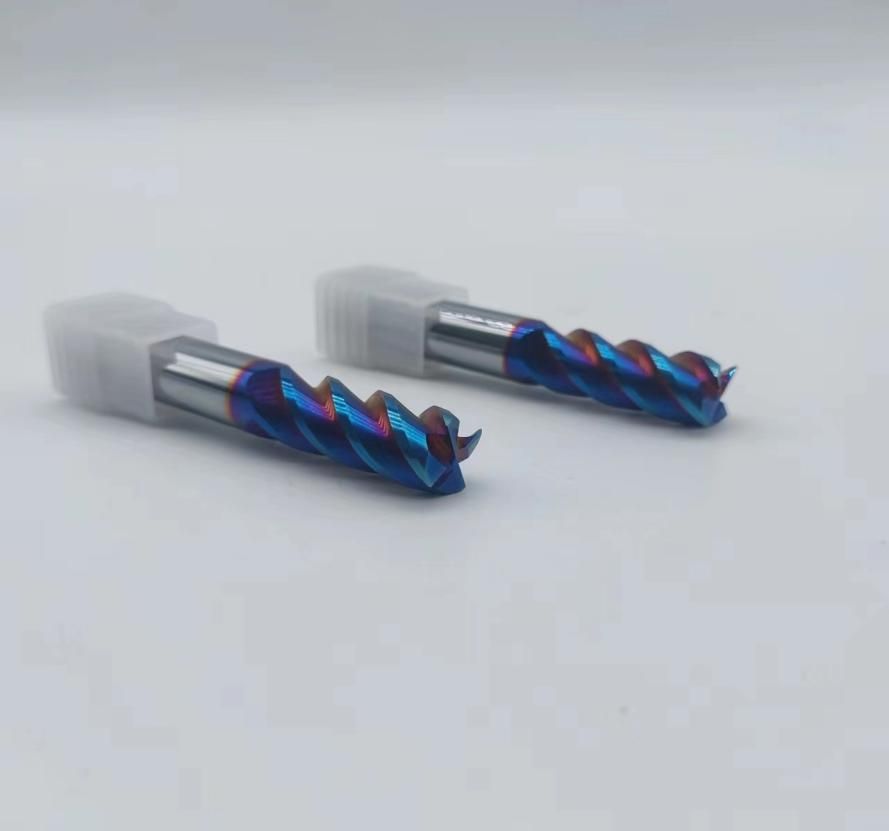

2.Tungsten carbide (WC) milling cutter: suitable for processing high hardness materials, such as titanium alloy, high hardness alloy steel, etc. Due to its high hardness, it is recommended for wet cooling.

3.PCD milling cutter (polycrystalline diamond): suitable for processing very hard materials, such as refractory materials, ceramics, glass, etc. Due to its poor heat dissipation, it must be used under wet cooling. When selecting the type of milling cutter, it should be considered according to the hardness, surface quality and processing volume of the processed material. Generally speaking, more teeth of the milling cutter can be used to improve surface smoothness, while fewer teeth can be used to increase processing speed, but care should also be taken to avoid excessive heat generation during use. In addition, the use of too small or too large milling cutters should be avoided, so as not to cause damage to too small milling cutters, and too large milling cutters will cause unbalanced processing and waste wear.

The service life of a milling cutter depends on many factors, such as the material, geometry, processing material, cutting force, cutting speed and cooling method of the milling cutter. Generally speaking, milling cutters will experience wear and fatigue during machining, making them lose their sharpness and accuracy, resulting in reduced product quality and reduced cutting efficiency.

In order to prolong the service life of the milling cutter, the following aspects should be paid attention to:

1.Select the appropriate milling cutter material and geometry, and choose according to the hardness, cutting speed and tool life requirements of the processed material.

2.Reasonably set the processing parameters, such as cutting speed, feed speed and cutting depth, etc., and avoid using excessively high cutting speed and feed speed to avoid excessive wear.

3.Keep milling cutters cool and lubricated, use proper coolants and lubricants to avoid excessive heat and wear.

4.Regularly clean and inspect the milling cutters, avoid the bad habit of accumulating chips and deposits, and regularly inspect and replace severely worn milling cutters.

5.Store and protect milling cutters from mechanical, chemical or corrosive damage, such as using professional drill boxes or jigs, and avoid exposure to harmful gases or direct sunlight.

Post time: Mar-13-2023