Carbide burr–Electric tool

Product introduction:

Carbide burrs are incredibly hard, allowing them to cut through tough materials with ease. They provide exceptional precision and control, making them ideal for intricate detailing and shaping. Carbide burrs are durable and have a longer lifespan compared to other cutting tools.They come in various shapes and sizes, making them suitable for a wide range of tasks and materials.

Carbide burrs can withstand high temperatures, reducing the risk of overheating during extended use. They minimize vibration, enhancing operator comfort and minimizing fatigue. Their efficient material removal and minimal clogging ensure a smoother workflow.Carbide burrs require minimal maintenance, saving time and effort. Despite the initial investment, their durability and performance make them cost-effective in the long run. Their longer lifespan reduces waste, promoting a more sustainable approach to manufacturing and craftsmanship.

We are a factory with 30 years of production experience in China, with customized customers throughout Europe, South America, and Southeast Asia.

Features:

1. Carbide burrs come in various shapes, such as cylindrical, ball, oval, tree, and more, allowing them to tackle a wide range of tasks. Whether you need to deburr, grind, shape, or carve, there's a rotary file suited to your needs.

2. The cutting edges of carbide burrs are typically made from tungsten carbide, a remarkably hard and durable material. This ensures that they can withstand the rigors of demanding applications and maintain their sharpness.

3. The sharp teeth or flutes on carbide burrs enable precise and controlled material removal. This makes them invaluable for intricate detailing, creating fine contours, and achieving high levels of accuracy.

4. Thanks to their tungsten carbide construction, carbide burrs have a longer lifespan compared to other cutting tools. They maintain their cutting efficiency over extended periods, reducing the need for frequent replacements.

5.Carbide burrs exhibit excellent heat resistance, crucial for applications that generate high temperatures during cutting. This feature prevents overheating, ensuring both tool and workpiece integrity.

6.They are designed to minimize vibration during operation, enhancing operator comfort and reducing fatigue. This is particularly important for tasks that require extended use.

7.Carbide burrs offer efficient material removal, reducing the time and effort required to complete tasks. Their design minimizes clogging and ensures a smoother workflow.

8. These tools are relatively low-maintenance, requiring only occasional cleaning and lubrication to keep them in optimal working condition.

Application:

Laser marking, customized brand general carbide burr handle.Brand labels can be attached to the outer packaging.

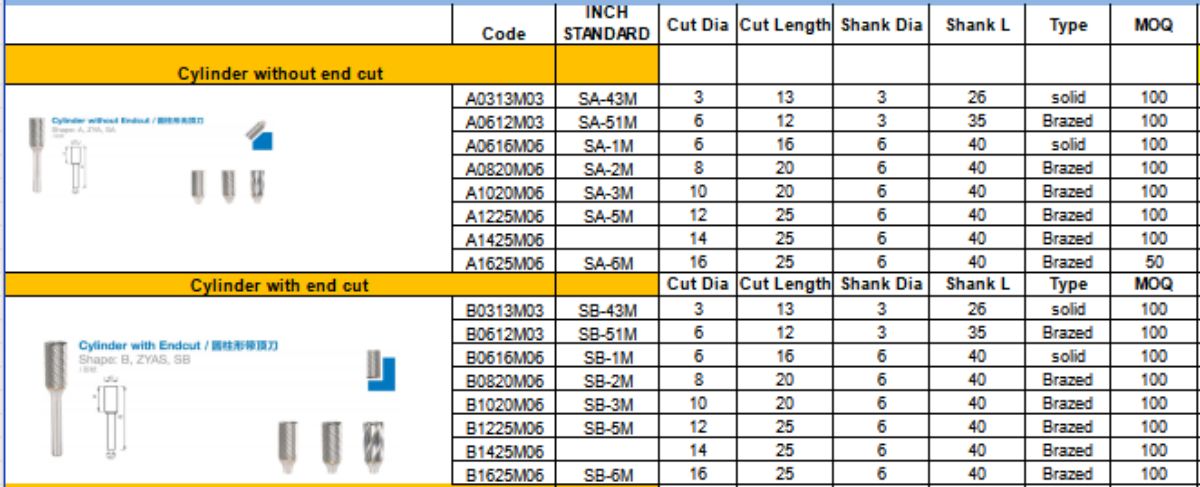

Parameters:

|

Material |

Tungsten |

|

Type |

A-T |

|

Cut |

Single and Double |

|

Welding Method |

Copper and Silver welding |

Samples:

Details

FAQ

1.Do you have a minimum order quantity?

Yes,the minimum order of each type is 100pcs.

2.Can you customize the brand?

Yes,we can do according the requirements of the customer.

3.What is the average lead time?

The delivery time is usually 10 to 30 days, depending on the product model and quantity of the order.

4.What kinds of payment methods do you accept?

You can make the payment to our bank account,Alibaba, Western Union or PayPal:

30% deposit in advance, 70% balance before shipping.