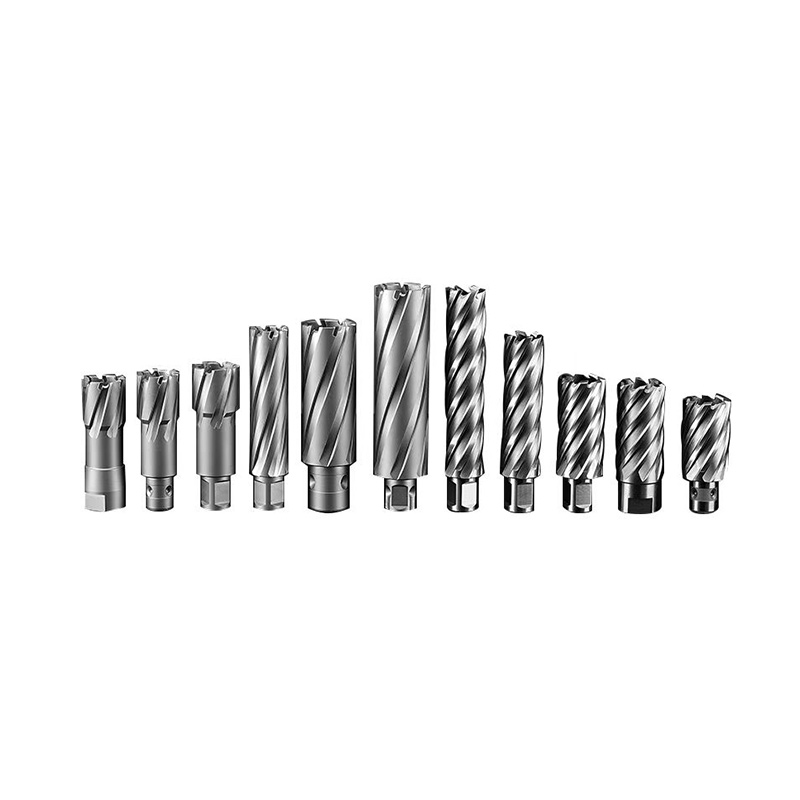

Carbide Annular Cutter With High Quality-Cutter Tool

RUIXIN TOOL-HSS Annular Cutter

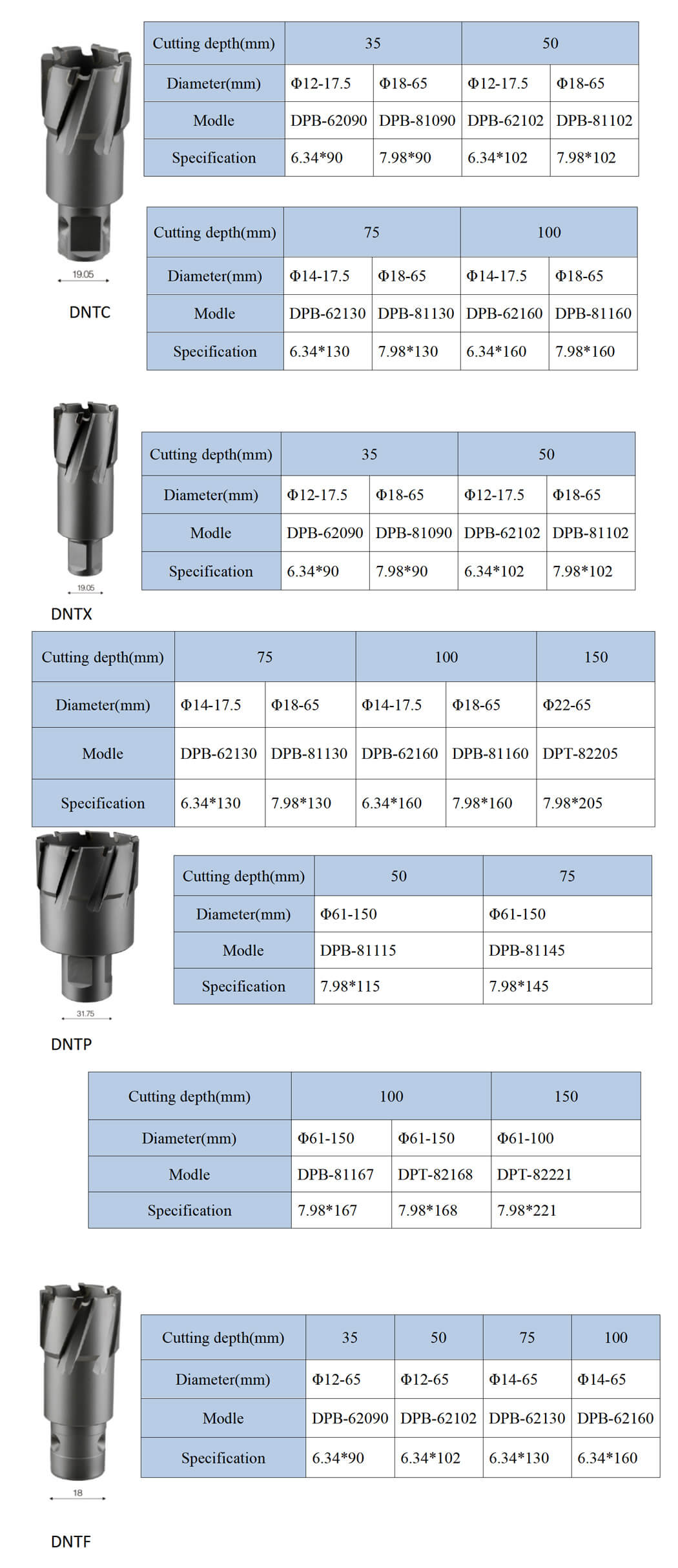

DNTC

DNTX

DNTP

DNTF

Product Information

Product Name:

1. Carbide annular cutter with universal shank (DNTC)

2. Carbide annular cutter with weldon shank (DNTX)

3. Carbide P-type annular cutter with weldon shank (DNTP)

4. Carbide annular cutter with FEIN Quick-IN shank (DNTF)

Product Diameter: 12-150mm

Product Cutting depth: 35mm, 50mm, 75mm, 100mm, 150mm

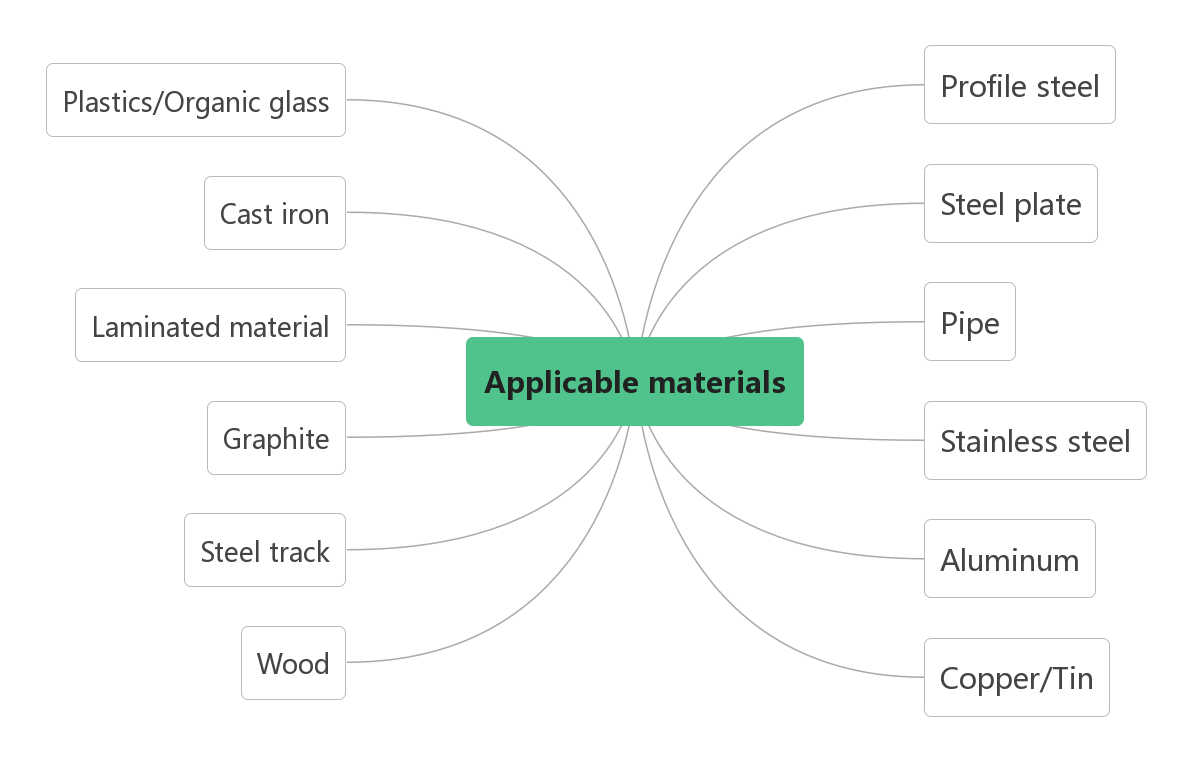

Product Application Materials: Suitable for all kinds of structural steel, alloyed steel, stainless steel, aluminum, brass, cast iron and so on.

Product Application Industry: Steel structure, bridge engineering, shipbuilding industry, oil drilling rig, railway construction, machine manufacturing, electric power and other fields.

Product Introduce: This product is a high speed drill for annular cutting with multiple blades. It is a hole processing tool suitable for portable tools, but can not process blind holes. Mainly used for drilling steel components, convenient and flexible operation, effectively shorten the construction time.

Model and Specification

| Carbide annular cutter with universal shank | DNTC-3 | DNTC-4 | DNTC-5 | DNTC-6 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 |

| Cutting depth(mm) | 35 | 50 | 75 | 100 |

| Carbide annular cutter with weldon shank | DNTX-3 | DNTX-4 | DNTX-5 | DNTX-6 | DNTX-7 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 | Φ22-65 |

| Cutting depth(mm) | 35 | 50 | 75 | 100 | 150 |

| Carbide P-type annular cutter with weldon shank | DNTP-4 | DNTP-5 | DNTP-6 | DNTP-7 |

| Diameter(mm) | Φ61-150 | Φ61-150 | Φ61-150 | Φ61-100 |

| Cutting depth(mm) | 50 | 75 | 100 | 150 |

| Carbide annular cutter with FEIN Quick-IN shank | DNTF-3 | DNTF-4 | DNTF-5 | DNTF-6 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 |

| Cutting depth(mm) | 35 | 50 | 75 | 100 |

Applicable Materials

Primary Competitive Advantages

1. With all handle types, it is suitable for all magnetic base drilling rigs in the world; Complete specifications, the maximum diameter of standard series is 150mm, the maximum cutting depth is 150mm, and the maximum diameter of customized series is 200mm Maximum cutting depth 200mm.

2. Adopt corresponding technical support schemes (round pipe and laminated cutting) according to different processing requirements.

3. Adopt matrix materials with excellent strength and toughness and special heat treatment process.

4. Adopt the design scheme of long and short grooves according to different drilling depths; Gradually open spiral groove structure, smooth chip removal and stable drilling.

5. Fully automatic CNC machine tool processing, with consistent and stable quality.

6. Imported high-performance cemented carbide blade and ultra-fine particles are adopted to ensure service life.

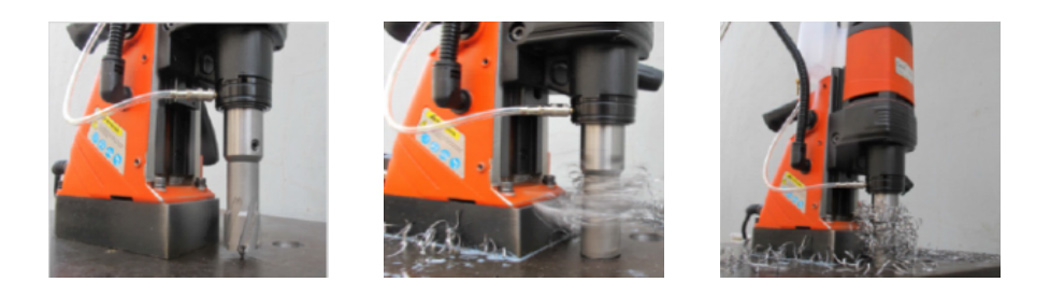

On-site Operation Drawing

Matters Needing Attention For Safe Operation

1. Please wear work clothes and protective glasses for operation to prevent iron filings from splashing and damaging skin and eyes.

2. Work when the product is installed correctly to prevent danger.

3. When installing and removing this product, please unplug the power plug or disconnect the power supply.

4. Heat is generated during drilling to avoid scalding and impact on the surrounding environment.

5. Do not modify this product without authorization, and then carry out drilling operation to prevent unforeseen things from happening.

6. During product rotation, it is strictly prohibited to touch with hands

7. In case of vibration, sharp sound and other abnormalities during operation, please stop the operation, check the product or replace it with a new one.

8. Please read the operating instructions of the drill and the machine before using the product.